Robots working inside the buildings at Fukushima Daiichi NPS (Part II) MHI-MEISTeR

– Images taken inside the Unit 2 Reactor building by the robot –

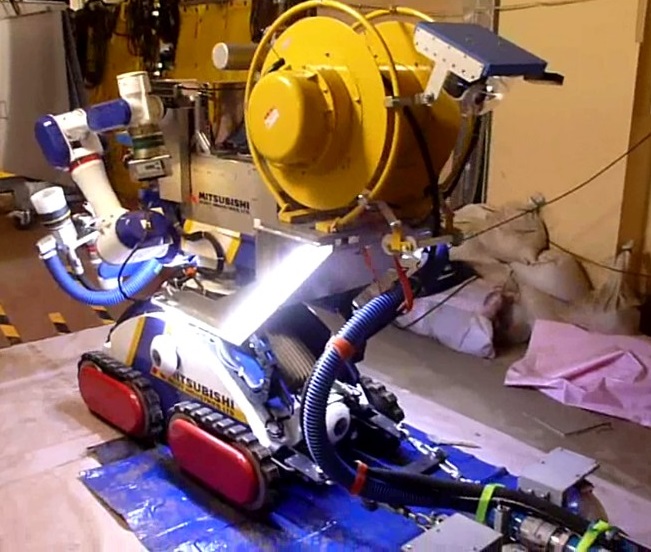

In the second part of our series of articles introducing robots working inside the buildings at the Fukushima Daiichi NPS, we look at the MHI-MEISTeR (Maintenance Equipment Integrated System of Telecontrol Robot), developed by Mitsubishi Heavy Industries.

In March 2014, MEISTeR conducted concrete core sampling in Unit 2 to determine the level of contamination of the operating floor and use the information gathered for making decisions in future about fuel removal methods.

Photos and videos of the robot in action and footage taken inside Unit 2 can be found below.

Before starting its operation, a large container housing MEISTeR was lowered onto the gantry of the blowout panel (safety feature that opens to relieve pressure when it drastically increases, etc.) of the Unit 2 wall surface. The robot was then sent to the operating floor by remote manipulation.

The core samples were collected from three locations on the operating floor. The operation was performed using the core boring apparatus equipped on one of MEISTeR’s arms, and the chisel (used to cut and shape metal and rock) on the other. The robot is electrically powered and designed to reduce the risk of oil leakage.

The core samples were then sent to the JAEA Oarai Research & Development Center and analyzed in detail.

- For details on MEISTeR’s specifications, please see the ‘R&D Topics’ page on the IRID website:

- https://irid.or.jp/en/topics/

- [Photos] Click image to enlarge.

- [Videos] Click “Download video” to download MP4 file.

[Videos]

-

MEISTeR sent into the reactor building for core sampling

-

MEISTeR leaving the container (Sped up x10)

-

Footage taken by MEISTeR’s camera (Sped up x10)

- Research and Development

- Survey Device (Shape-changing Robot) Deployed to Inspect Interior of Primary Containment Vessel (PCV)

- Work Training of Device (Shape-changing Robot) to Inspect Interior of Primary Containment Vessel (PCV) [Hitachi-GE Nuclear Energy]

- Development status of equipment for internal PCV investigation [TOSHIBA]

- Robots working inside the buildings at Fukushima Daiichi NPS (Part III) Swimming robot & Crawling robot

- Robots working inside the buildings at Fukushima Daiichi NPS (Part II) MHI-MEISTeR

- Robots working inside the buildings at Fukushima Daiichi NPS Rosemary & Sakura

- Development Status of PCV Leakage Investigation Devices (Toshiba)

- Preliminary Test for “Water Stoppage Method” by Grouting into the Vent Pipe