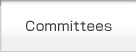

Development of “Laser Gouging Technology” for Fuel Debris [Led by Toshiba] (October 28, 2016)

Oct.28,2016

IRID (with development led by Toshiba) is conducting development of fundamental technology for retrieval of fuel debris and reactor internals under the subsidy project of Decommissioning and Contaminated Water Management, as a part of R&D challenges towards the decommissioning of Fukushima Daiichi Nuclear Power Station (NPS).

Development of Repair Technology for Water Leakage Sections in PCV Testing Concrete Injection Technology for Water Leak Stoppage Treatment inside Suppression Chamber Using Full-Scale Mock-up Facility [Led by TOSHIBA]. (October 15, 2016)

Oct.15,2016

IRID is advancing the development of repair technology for water leakage sections in the Primary Containment Vessel (PCV) under a project led by Ministry of Economy, Trade and Industry (METI) in FY 2016-FY 2017 towards the decommissioning of the Fukushima Daiichi Nuclear Power Station (NPS). As a part of this project, a method of injecting concrete to repair water leakage points inside suppression chamber (S/C), a structure that lies at the lower part of the PCV, is currently being examined.

Completion of Preparation for Full-Scale Test Facility Simulating the Lower Part of the PCV and Future Test Plans (October 13, 2016)

Oct.13,2016

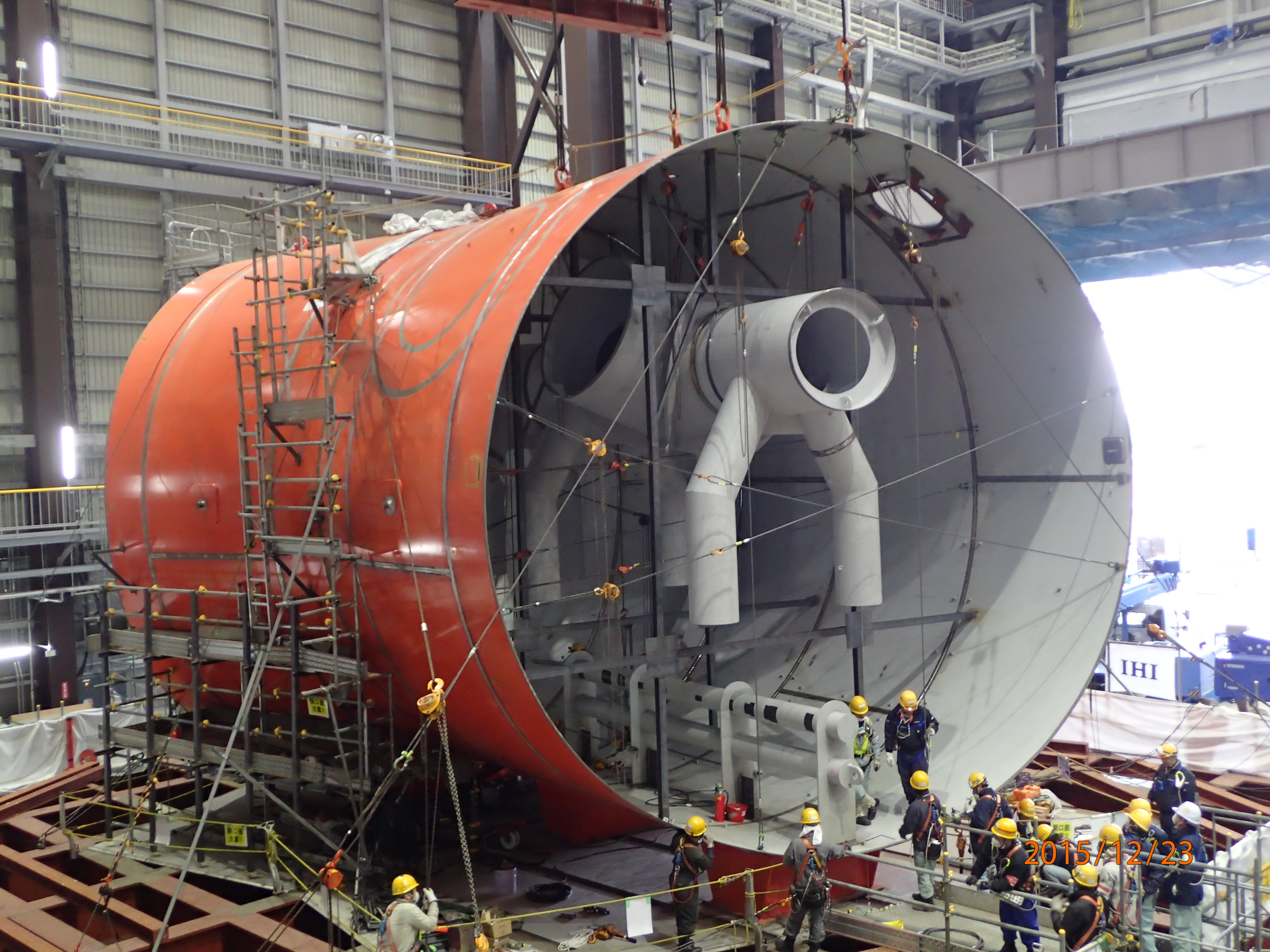

A full-scale mock-up facility* is now ready for testing purposes to establish technology for repairing water leakage points in the lower part of the Primary Containment Vessel (PCV).

* This test facility simulates vent pipes, the suppression chamber (S/C), and torus room wall found in the lower part of the PCV in Fukushima Daiichi Nuclear Power Station (NPS) Unit 2. The facility is of full-scale size, but represents a 1/8 portion of the circular S/C.

Completed manufacturing a full-scale test device simulated the lower part of the Primary Containment Vessel (PCV) and its test plan. (April 20, 2016)

Apr.20,2016

The International Research Institute for Nuclear Decommissioning (IRID) manufactured “full-scale test device” in the Naraha Remote Technology Development Center in order to establish the technology for repair and water leakage stoppage in the lower part of the PCV.

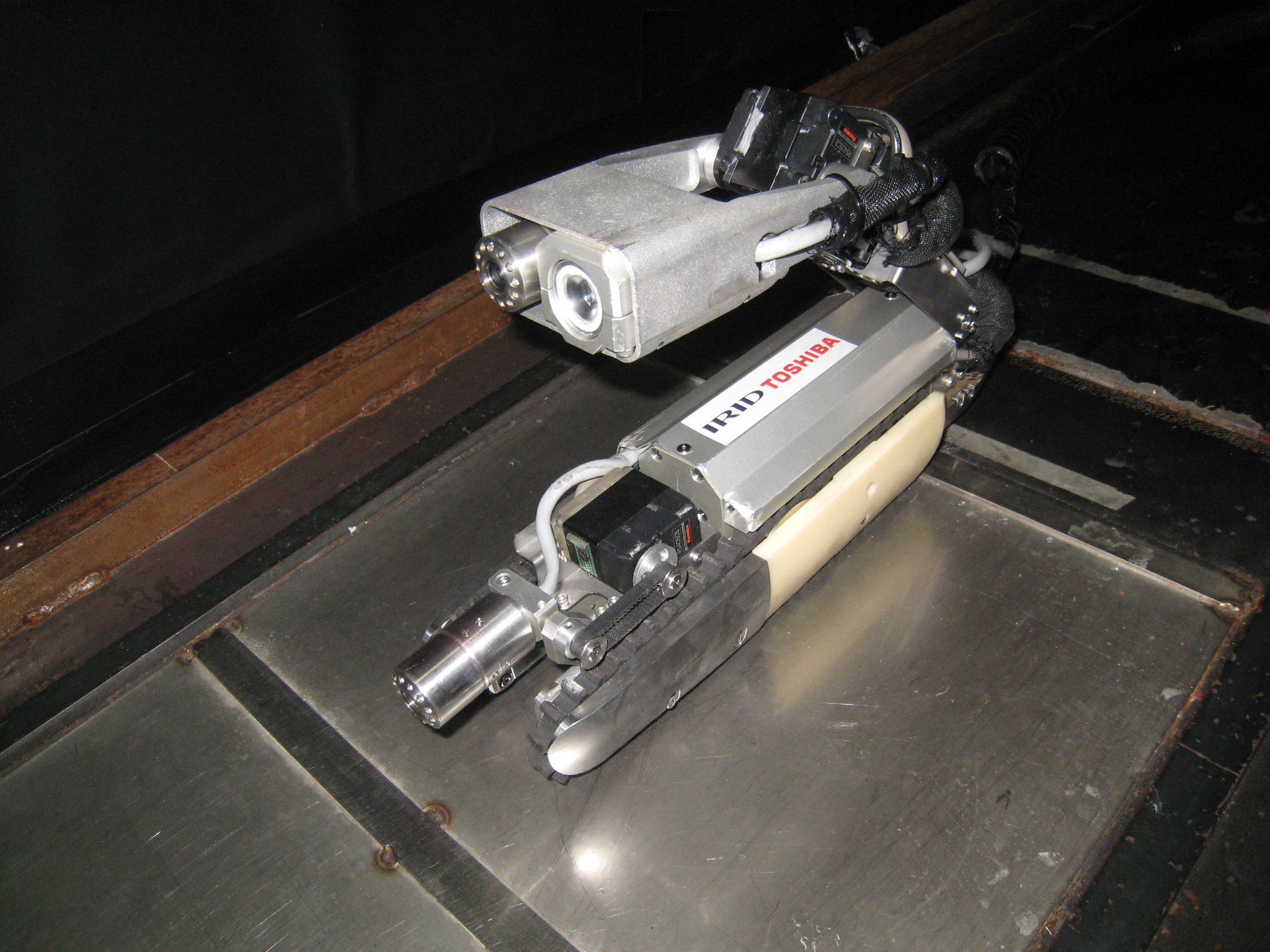

Improved Robot for Investigation inside the Primary Containment Vessel (Scorpion Robot) [Developed by TOSHIBA CORPORATION] (Feb. 18, 2016)

Feb.18,2016

IRID plans to deploy an improved remotely-operated robot (scorpion robot) to investigate inside the Primary Containment Vessel (PCV) at the Fukushima Daiichi Nuclear Power Station Unit2 as soon as it completes on-site preparations, including investigation and decontamination work around a penetration that is to be used as an insertion opening through which the investigation robot will be inserted.

Development of decontamination equipment for upper floors of the reactor building at the Fukushima Daiichi Nuclear Power Station (Dec.16, 2015)

Dec.16,2015

.jpg)

IRID is developing decontamination equipment for upper floors—a new robot for decontaminating the second and third floors of the reactor building at the Fukushima Daiichi Nuclear Power Station (NPS).

[Videos] Operations Training for Investigation inside the Primary Containment Vessel (PCV) at the Fukushima Daiichi Nuclear Power Station (NPS) Unit 2 and Equipment for Preliminary Investigation inside the Pedestal and Deposit Removal Equipment (Oct. 14, 2015)

Oct.14,2015

The inside of the PCV at the Fukushima Daiichi NPS Unit 2 is to be investigated by deploying the remotely-operated robot (scorpion robot) in place as soon as on-site preparations are completed, including investigation of the periphery of the penetration through which the investigation robot will be inserted.

Below are five videos, including one showing TOSHIBA CORPORATION, an IRID member, conducting training in preparation for the investigation inside the PCV this summer.

Development and Utilization of Dry Ice Blast Decontamination Equipment for High Places (Sept. 8, 2015)

Sep.08,2015

The decontamination work in reactor buildings at the Fukushima Daiichi Nuclear Power Station (NPS) must be accelerated as early as possible because radiation doses there are currently high and therefor workers are not able to put in long hours.

Training on use of ‘TEMBO’ equipment to remove shielding blocks and iron plates now underway (Mitsubishi Heavy Industries)

May.28,2015

IRID plans to use a miniature robot to investigate (‘A2 Investigation’) the inside of the Fukushima Daiichi Unit 2 primary containment vessel (PCV). This investigation will see the robot make its way the point directly below the reactor pressure vessel and making full use of an onboard camera, in addition to other devices, measure radiation and temperature levels and have it collect vital data for the consideration of various decommissioning scenarios.

Commencement of Reactor Interior Survey Using ‘Muon Transmission Method’ (February 12, 2015)

Feb.12,2015

A survey of the interior of Unit 1 at the Fukushima Daiichi Nuclear Power Station (NPS) using the ‘muon transmission method’ began on February 12, 2015.

In order for the decommissioning of the damaged reactors at the Fukushima Daiichi NPS to proceed, molten fuel debris inside the reactors must first be retrieved. However, radiation levels are extremely high, preventing workers from entering the reactor building and directly observing the condition and location of the fuel in the cores.