Development of “Laser Gouging Technology” for Fuel Debris [Led by Toshiba] (October 28, 2016)

Oct.28,2016

IRID (with development led by Toshiba) is conducting development of fundamental technology for retrieval of fuel debris and reactor internals under the subsidy project of Decommissioning and Contaminated Water Management, as a part of R&D challenges towards the decommissioning of Fukushima Daiichi Nuclear Power Station (NPS).

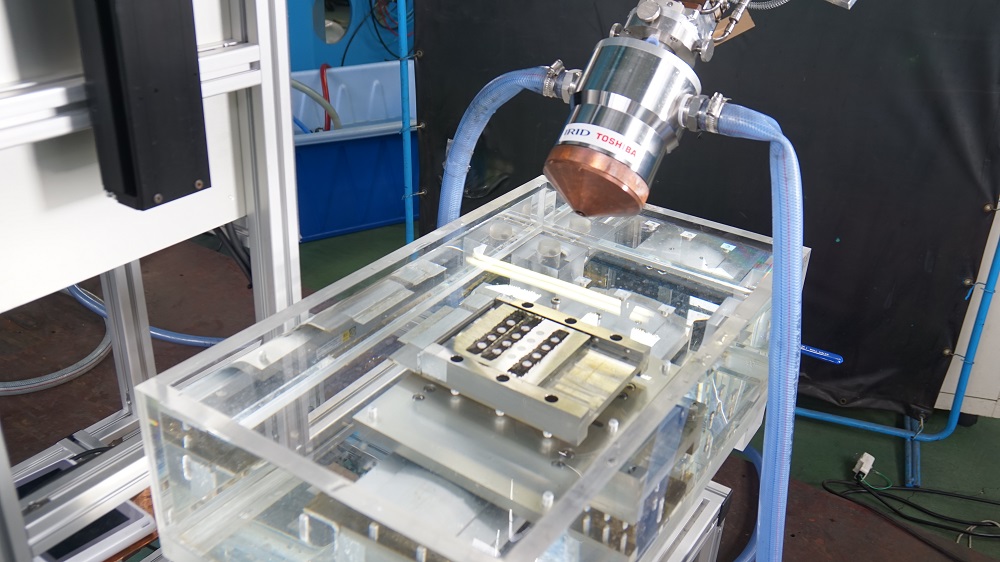

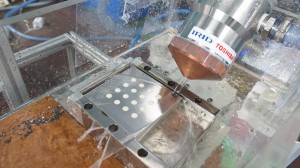

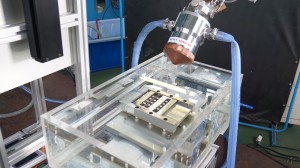

“Laser Gouging Technology” is one of the technologies in order to process fuel debris to be stored in a canister. Gouging process testing was performed simultaneously using water jet injection and laser irradiation in the air and underwater environments.

[Testing Overview]

Gouging process tests were performed simultaneously using water injection and laser irradiation in air/underwater environments. The test verified that processing is possible for all of stainless steel, high-melting-point aluminum oxide and zirconium oxide as well as confirming the feasibility of laser gouging technology for fuel debris.

The test showed no difference in performance between air and underwater environments. Processing speed of zirconium oxide and aluminum oxide also showed no great difference.

The test showed that there is a correlation with distance and processing speed between gouging nozzle and materials.

[Future Developments]

Verification test will be conducted on the amount of free particles and distribution of actual application, when the research is continued after FY2017.

<Attachment: “Purpose of Fuel Debris Processing”, ”Overview of Laser Gouging Technology”, “Feature of Laser Gouging Technology under Development”>

https://irid.or.jp/wp-content/uploads/2016/10/20161031_01.pdf

<Video footage> * Link to the YouTube site.

|

<Reference>

|

|

| Photo 1 | Photo 2 |

|

|

| Photo 3 | Photo 4 |

|

|

| Photo 5 |

Inquiries regarding this topic may be directed to IRID via E-mail