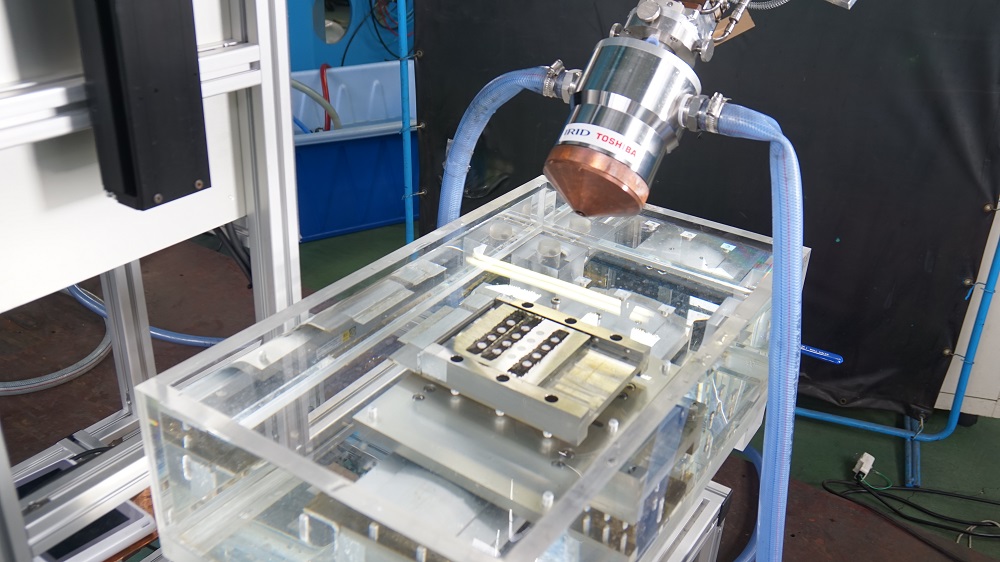

Development of “Laser Gouging Technology” for Fuel Debris [Led by Toshiba] (October 28, 2016)

Oct.28,2016

IRID (with development led by Toshiba) is conducting development of fundamental technology for retrieval of fuel debris and reactor internals under the subsidy project of Decommissioning and Contaminated Water Management, as a part of R&D challenges towards the decommissioning of Fukushima Daiichi Nuclear Power Station (NPS).

Development of Repair Technology for Water Leakage Sections in PCV Testing Concrete Injection Technology for Water Leak Stoppage Treatment inside Suppression Chamber Using Full-Scale Mock-up Facility [Led by TOSHIBA]. (October 15, 2016)

Oct.15,2016

IRID is advancing the development of repair technology for water leakage sections in the Primary Containment Vessel (PCV) under a project led by Ministry of Economy, Trade and Industry (METI) in FY 2016-FY 2017 towards the decommissioning of the Fukushima Daiichi Nuclear Power Station (NPS). As a part of this project, a method of injecting concrete to repair water leakage points inside suppression chamber (S/C), a structure that lies at the lower part of the PCV, is currently being examined.

Completion of Preparation for Full-Scale Test Facility Simulating the Lower Part of the PCV and Future Test Plans (October 13, 2016)

Oct.13,2016

A full-scale mock-up facility* is now ready for testing purposes to establish technology for repairing water leakage points in the lower part of the Primary Containment Vessel (PCV).

* This test facility simulates vent pipes, the suppression chamber (S/C), and torus room wall found in the lower part of the PCV in Fukushima Daiichi Nuclear Power Station (NPS) Unit 2. The facility is of full-scale size, but represents a 1/8 portion of the circular S/C.