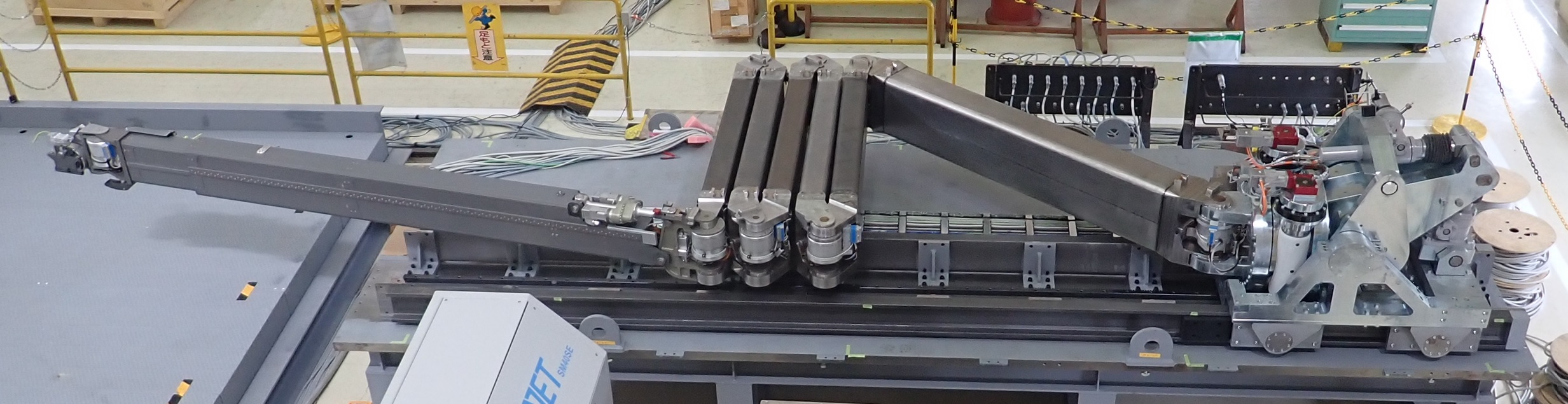

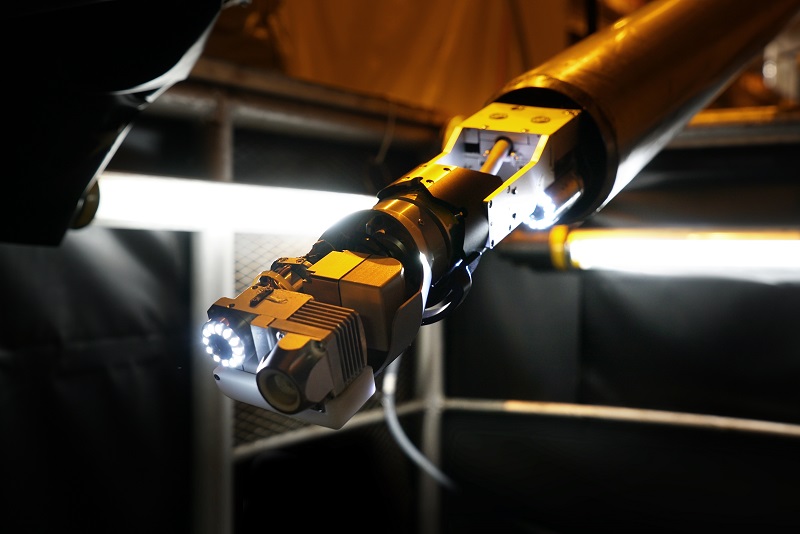

Detailed investigation inside PCV of Fukushima Daiichi NPS Unit 2, and verification test for access and investigation equipment for fuel debris test retrieval at Kobe Shipyard & Machinery Works Kobe Plant, MHI, Ltd. [Developed by Mitsubishi Heavy Industries (MHI), Ltd.]

Mar.09,2022

The International Research Institute for Nuclear Decommissioning (IRID) has been developing access and investigation equipment for detailed investigation inside the primary containment vessel (PCV) and fuel debris test retrieval (the robot arm and the enclosure) for Fukushima Daiichi Nuclear Power Station (NPS) Unit 2 toward the decommissioning of Fukushima Daiichi NPS, Tokyo Electric Power Company Holdings, Inc.

The equipment was transported from United Kingdom to Kobe Shipyard & Machinery Works Kobe Plant, MHI Ltd. in July 2021. A verification test for the equipment was conducted in Kobe during the period from late August of 2021 to January 21, 2022.

This article is provided to introduce a video of the verification test of the robot arm conducted at Kobe Shipyard & Machinery Works Kobe Plant. In addition, this equipment is acquired from a subsidy project of Countermeasures for Decommissioning and Contaminated Water granted by the Ministry of Economy, Trade and Industry.

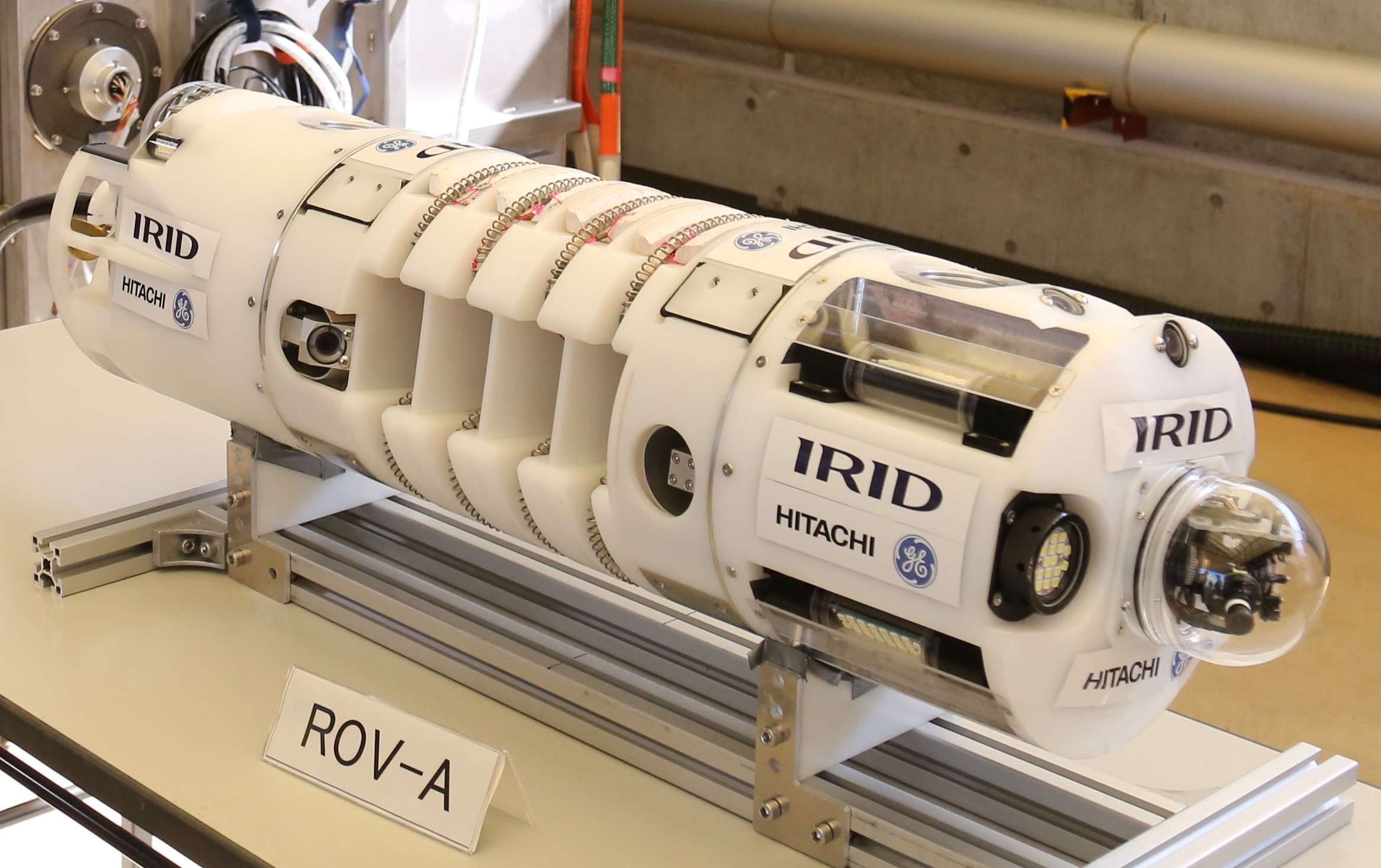

Boat-type Submersible Access Devices to Investigate Interiors of PCV at Fukushima Daiichi Nuclear Power Station[Developed by Hitachi GE Nuclear Energy, Ltd. in 2019]

Oct.25,2019

For the decommissioning of the Fukushima Daiichi Nuclear Power Station (NPS), owned by the Tokyo Electric Power Company Holdings, Inc. (TEPCO), the International Research Institute for Nuclear Decommissioning (IRID) has developed the boat-type submersible access devices and small-type remotely operated vehicles (ROVs) to investigate the details of the Unit 1 primary containment vessel (PCV) at the Fukushima Daiichi NPS. Here, IRID introduces line-up of the devices.

These devices are the results of a subsidy project on decommissioning and contaminated water management in the fiscal year of 2017 of the Development of Technologies for Detailed Investigation inside PCV (onsite-demonstration of detailed investigation technologies considering management of deposits), which is granted by the Agency of Natural Resources and Energy (ANRE) and the Ministry of Economy, Trade and Industry (METI).

An Operation Confirmation Test for a Robot Arm and Access Rail: Element Technology for Retrieving Fuel Debris using a Partial Submersion Side-Access Method.[Developed by Mitsubishi Heavy Industries, Ltd.]

Oct.10,2019

Fuel debris retrieval in the Fukushima Daiichi Nuclear Power Station is planned to start with a small-scale retrieval. As the review of the retrieval work, conducted flexibly on the basis of fuel debris properties and new findings obtained from the work experience, progresses, the scale of retrieval will be increased.A robot arm and access rail have been developed as one of element technologies for retrieving fuel debris using a partial submersion side-access method. These have been created to be used as the scale of fuel debris retrieval expands.

Development of a Small-amount Fuel Debris Sampling Device for the Detailed Investigation inside the Primary Containment Vessel [Developed by Mitsubishi Heavy Industries] (August 2019)]

Aug.31,2019

A sampling device used for collecting small amounts of fuel debris was developed for decommissioning the Tokyo Electric Power Company (TEPCO) Holdings, Inc. Fukushima Daiichi Nuclear Power Station (NPS). It was developed using an ultrafine metal wire brush method for the detailed investigation inside the Primary Containment Vessel (PCV) at Unit 2 of the Fukushima Daiichi NPS, The device was introduced to the public at the International Research Institute for Nuclear Decommissioning (IRID) Symposium 2019, held on August 1, 2019.

Investigation Inside PCV / Development of a Device to Investigate inside PCV of Fukushima Daiichi NPS Unit 2 [Development by Toshiba Energy Systems & Solutions Corporation] (December 22, 2017)

Dec.22,2017

As part of decommissioning activities for the Fukushima Daiichi Nuclear Power Station (NPS), operated by Tokyo Electric Power Co. (TEPCO), an investigation device was developed to survey the internal conditions of the pedestal in the primary containment vessel (PCV) of Fukushima Daiichi NPS Unit 2. The investigation device was released to the media on December 22, 2017.

Full-scale Test for Repair Technology for Leakage Points inside the Primary Containment Vessel: Reinforcement of Suppression Chamber Support Columns [IRID / Hitachi GE Nuclear Energy] (July 31, 2017)

Jul.31,2017

IRID is engaged in the ongoing development of technology for repairing leakage points in the Primary Containment Vessel (PCV) under a project sponsored by the Ministry of Economy, Trade and Industry (METI) between FY2016 and 2017 for the decommissioning of the Fukushima Daiichi Nuclear Power Station (NPS). As part of this project, IRID conducted testing of technology for the reinforcement of suppression chamber (S/C) by injecting mortar.

Full-scale testing of PCV Leakage Point Repairing Technology : Full-scale testing of Water Stoppage Technology by Filling in Suppression Chamber (S/C) [IRID / TOSHIBA] (June 24, 2017)

Jun.24,2017

IRID is engaged in the ongoing development of technology for repairing leakage points in Primary Containment Vessels (PCVs), under a project sponsored by the Ministry of Economy, Trade and Industry (METI) for the FY 2016–2017 period, aimed at the decommissioning of the Fukushima Daiichi Nuclear Power Station (NPS). As part of this project, IRID conducted tests to stop water leakage in the suppression chamber (S/C) by injecting concrete.

Development of technology for criticality control in fuel debris retrieval: Development of “critical approach monitoring method” using Kyoto University Critical Assembly (KUCA) (June 21, 2017)

Jun.21,2017

It is confirmed through the monitoring system that fuel debris is not currently in a critical state. Since the shape of fuel debris and water level may change during fuel debris retrieval in the future, the possibility of criticality configuration is considered to be very small. However, we are promoting development of sub-criticality monitoring technology and criticality prevention technology to ensure prevention of criticality, and also safely terminate criticality, even if it occurs.

Investigation inside Primary Containment Vessel (PCV): Development of Submersible Crawling Robot to Survey inside PCV of Fukushima Daiichi Unit 3 [Development by TOSHIBA] (June 15, 2017)

Jun.15,2017

As part of the decommissioning activities for the Fukushima Daiichi Nuclear Power Station, operated by Tokyo Electric Power Co., (TEPCO), a small submersible crawling robot was developed to investigate the internal surroundings of the pedestal, under the Reactor Pressure Vessel (RPV), in the PCV of Unit 3, where coolant water had accumulated. The robot was released to the media on June 15, 2017.

Study on Fuel Debris Retrieval Method: “Reactor Pressure Vessel 1/1 Scale Model Test”, etc. [Development by Hitachi GE Nuclear Energy] (April 2017)

Apr.17,2017

As part of its R&D efforts for the decommissioning of the Fukushima Daiichi Nuclear Power Station (NPS), the IRID (development by Hitachi GE Nuclear Energy) is involved in developing fundamental technologies for the retrieval and removal of fuel debris and internal reactor structures, and subsidizing costs for the Decommissioning and Contaminated Water Management Project.