Development of decontamination equipment for upper floors of the reactor building at the Fukushima Daiichi Nuclear Power Station (Dec.16, 2015)

Dec.16,2015

.jpg)

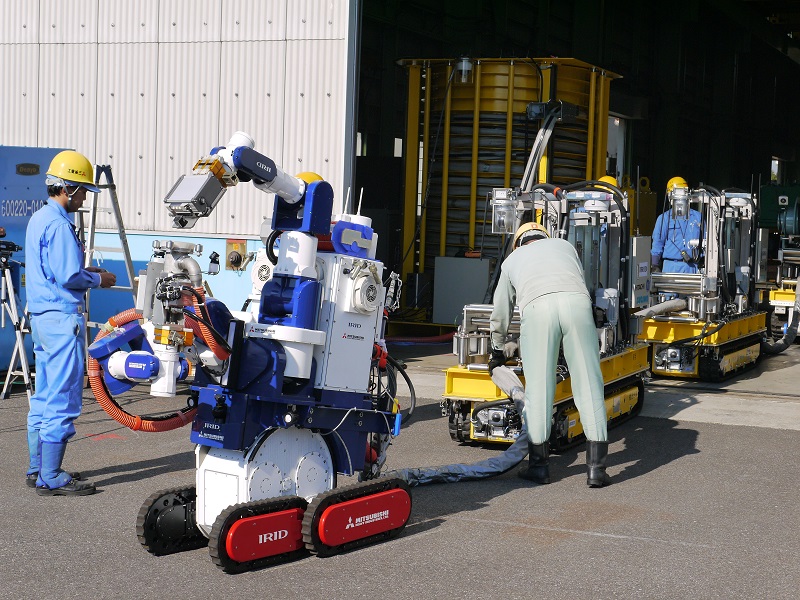

IRID is developing decontamination equipment for upper floors—a new robot for decontaminating the second and third floors of the reactor building at the Fukushima Daiichi Nuclear Power Station (NPS).

Various kinds of work such as the investigations and repairs of water leakage points will start on a full scale toward fuel debris retrieval, based on the progress status of R&D etc. For this, the environment of the work areas where radiation doses are high should be improved so that workers can enter the areas.

The equipment under development is to be used to decontaminate the second and third floors of the reactor building which have not been decontaminated yet.

Three IRID members Mitsubishi Heavy Industries, Ltd., Hitachi-GE Nuclear Energy, Ltd. and TOSHIBA CORPORATION are cooperating with each other in developing the equipment by utilizing organizational advantages of the technology research association called IRID, based on the site information and needs from Tokyo Electric Power Company, Incorporated (TEPCO). This cooperation is enabling IRID to concentrate the technology of the manufactures and thereby develop more efficient decontamination equipment that meets the needs of the Fukushima Daiichi site. This is the first time that the three manufacturers share design information among them to develop a piece of equipment (system).

IRID has repeatedly conducted verification tests on the equipment using a mock-up facility that simulates the inside of the actual reactor building since September 2015 and thus verified the operability, running and decontamination performances of the remotely-operated equipment, responses in its failure, etc.

We will reflect knowledge obtained through the demonstration tests in the development of the equipment and prepare to put it in practical use in the Fukushima Daiichi NPS in FY 2016 and beyond.

[The basic outline of the equipment]

◆ Targets of decontamination: The floor and wall surfaces in the second and third floors (about 2 m in height)

◆ Decontamination methods: Four types of technology: suction; blast; dry ice blast; and high-pressure water jet

* Wheeled platforms are designed for common use so that a decontamination unit carried on each wheeled platform can be replaced with another one, according to an applied decontamination method.

◆ Access to the upper floors: Entry from an equipment hatch using a lifting device (something like an elevator)

[Decontamination equipment for the upper floors (Video)] * Link to the YouTube site.

|

[Decontamination equipment for the upper floors (Photos)]

|

|

|

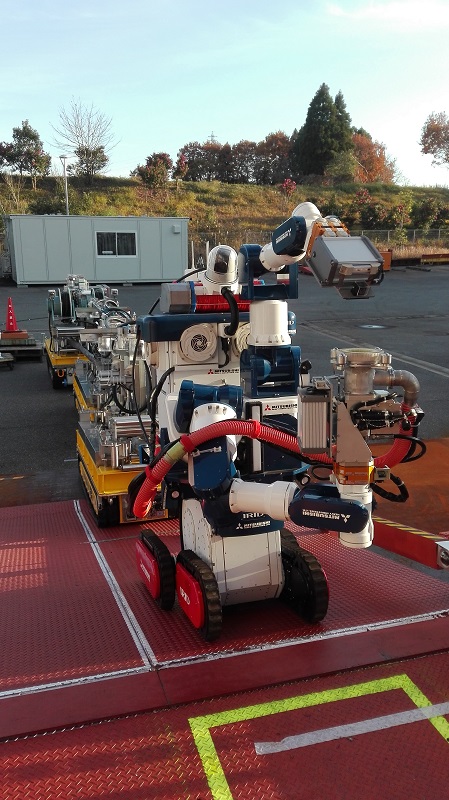

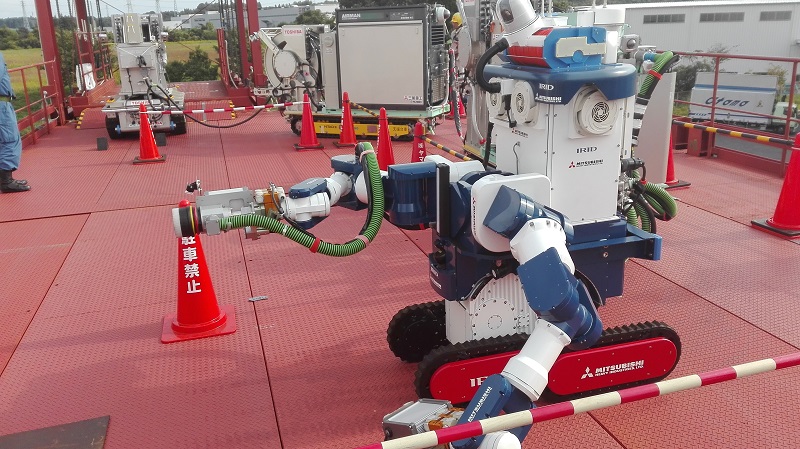

| Moving the equipment (high-pressure water jet type) | Conducting the running test on a narrow space | Moving the equipment (suction and blast decontamination type) |

|

|

|

| Moving the equipment onto the lifting device 1 | Moving the equipment onto the lifting device 2 | Inspecting the verification test |

|

|

|

| Moving the equipment onto the lifting device 3 | Moving the equipment up and down | Moving the equipment on the upper floor (the second floor) of the mock-up facility |

|

|

|

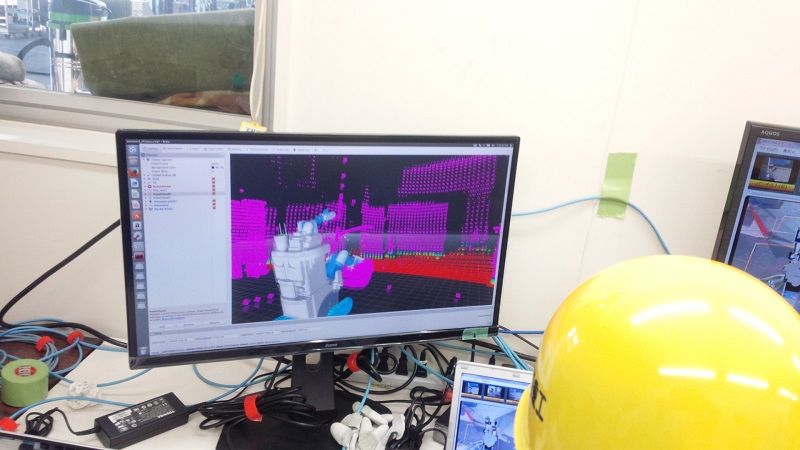

| Conducting the decontamination test | Conducting the decontamination test (high-pressure water jet equipment type) | Remotely operating the equipment 1 |

|

|

|

| Remotely operating the equipment 2 | Remotely operating the equipment 3 |