Completed manufacturing a full-scale test device simulated the lower part of the Primary Containment Vessel (PCV) and its test plan. (April 20, 2016)

Apr.20,2016

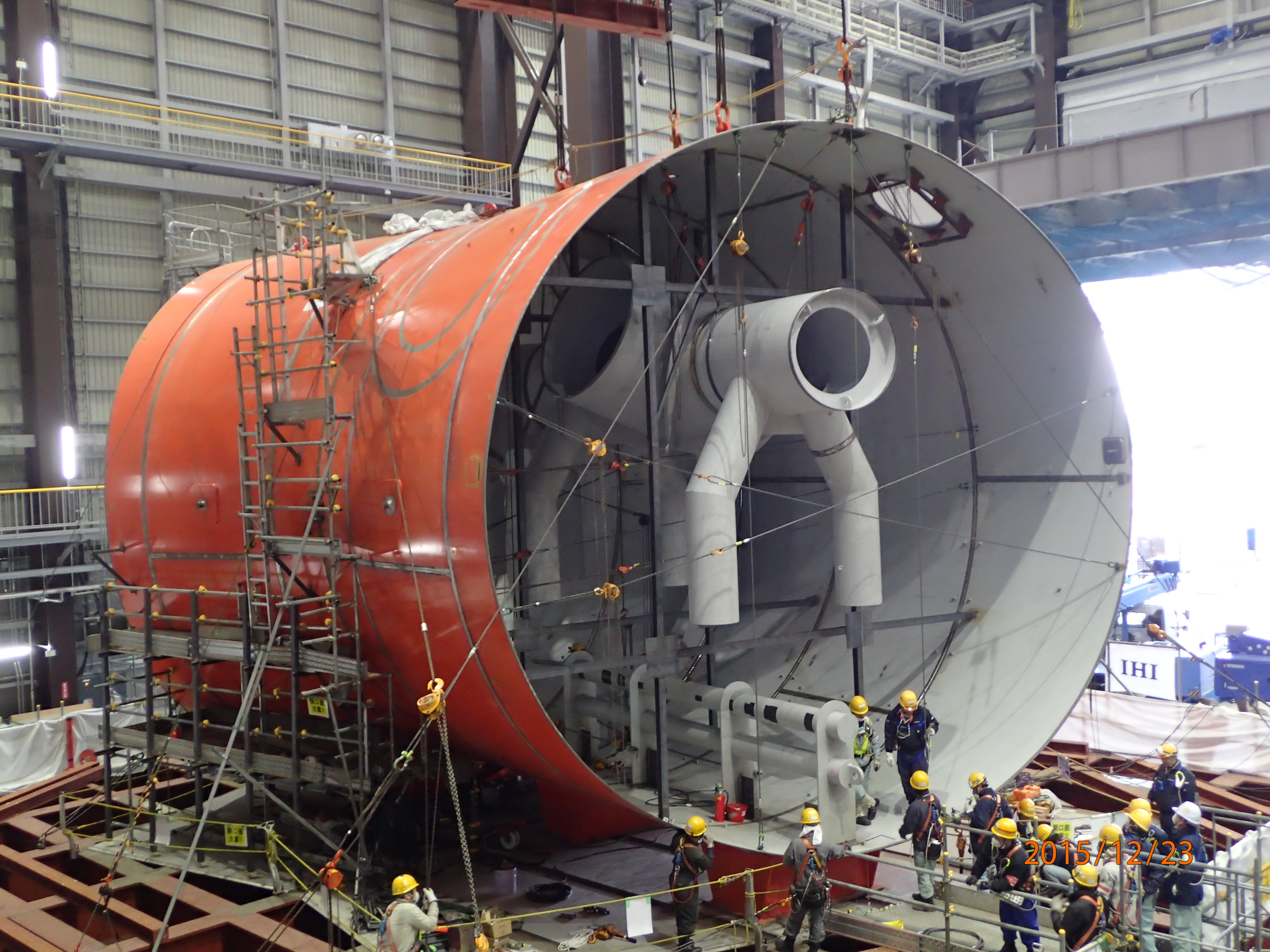

The International Research Institute for Nuclear Decommissioning (IRID) manufactured “full-scale test device” in the Naraha Remote Technology Development Center in order to establish the technology for repair and water leakage stoppage in the lower part of the PCV.

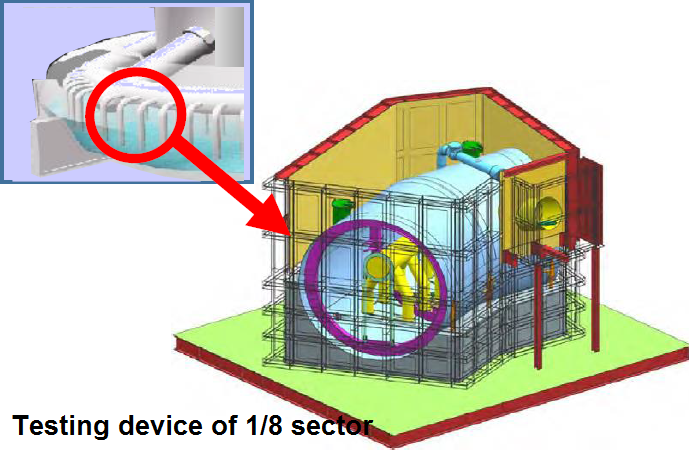

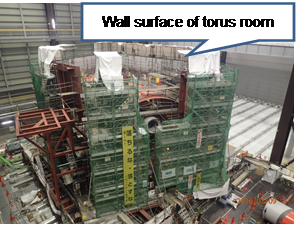

This test device was simulated a vent pipe, the suppression chamber (S/C) and wall surface of torus room at the lower part of the PCV at the Fukushima Daiichi Nuclear Power Station (NPS) Unit 2. The test device is full-scale, however, its shape is an original part divided into eight equal parts of the S/C that is circumference shape (Refer to Figure 1, Figure 2).

IRID has conducted elemental testing to develop the technology for repair and water leakage stoppage at the lower part of the PCV (technology for strengthening the S/C support columns, water stoppage technology involving injection of sealing material into the vent pipe, development of technology for water leakage stoppage with filling in the S/C and etc. ) in plants from FY 2014 – FY2015.

Full-scale testing will be conducted using this test device with combination of the elemental test results and confirming procedure of on-site work via remote control from now on. Furthermore, we are planning to gather knowledge and ideas for the development of the technology for repair at the lower part of the PCV. (Period of research: for 2 years from FY 2016 ~ FY2017)

[Future plans]

After autumn in FY 2016: Mortar filling testing for strengthening the S/C support columns

FY 2017: Testing for water stoppage in vent pipe and water stoppage with filling in the S/C (down comer water stoppage)

|

|

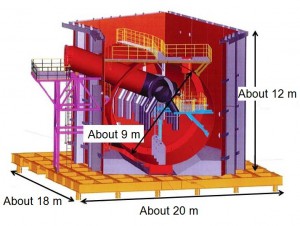

| (Figure 1) Image of testing device | (Figure 2) size of testing device |

[Manufacturing process of full-scale testing device]

|

|

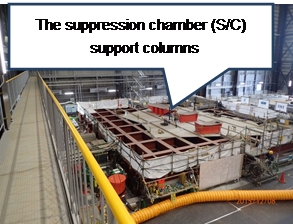

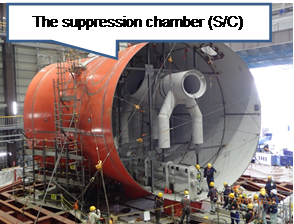

| Installed S/C support columns (Taken image on December 8, 2015) | Installed S/C (Taken image on December 23, 2015) |

|

|

| Installed wall surface of torus room (Taken image on February 9, 2016) | Installed a vent pipe (Taken image on February 15, 2016) |

Click here to see manufacturing process of testing device in detail.

[Reference]

・IRID Annual Research Report 2015

Development of repair and water leakage stoppage technology for leakage points inside the PCV

Full-scale test for repair and water leakage stoppage technology for leakage points inside the PCV

[Held the opening ceremony of the test building in the Naraha Remote Technology Development Center]

The opening ceremony of the test building in the Naraha Remote Technology Development Center was held in March 30, 2016. IRID members attended the ceremony and introduced full-scale test device for guests and news media.

|

|

| Observing the test device after the ceremony (in front of full-scale test device) | Introduce full-scale test device for guests (Explained by Mr. Kuwabara, general manager, R&D strategy planning department, IRID) |

|

|

| Taken full-scale test device from the third floor at the test building |

Inquiries regarding this topic may be directed to IRID via E-mail